Keeping Our Cool: Powertrain Cooling Testing

Following last year’s Australasian competition, it was clear that powertrain had a bit of work to do in the 2016 design period. One of our main aims for the M15R and M16 cars is to sufficiently cool the powertrain package and keep the engine within its optimum operating temperature.

Sounds easy enough right? Let’s keep in mind that this engine was not designed for the conditions we expose it to every time it runs. At the end of the day the more power you produce, the more heat it will exchange. It was clear that we would have to sacrifice weight for cooling, as there is no use having a weapon of a car if it overheats and costs you the competition.

The main change to the cooling system is the transition to twin side-mount radiators, compared to 15’s single side-mount. Extensive testing was carried out early in the year comparing many different configurations. This even included having a radiator almost triple the size mounted at the rear of the car. Due to airflow, packaging and control restraints, we soon came to the conclusion that twin side-mount radiators would best suit our application.

Once the twin system was decided on, there were a couple more parameters to consider. A big choice to be made was whether the radiators should be plumbed in series or parallel. Upon consultation with senior team members and alumni, a parallel system was set up for testing. Parallel meant that we would see a higher difference in fluid temperature across both radiators with less flow restriction. The plumbing of the system was a big job, but was made easier by the mass supply of hoses & fasteners from Dayco.

To increase the airflow through the radiators at low speeds, we considered running dual fans and carbon shrouds. Due to electrical power limitations faced with not running an external alternator, it was decided that we should compromise and use the Davies Craig DC fan on the primary radiator only.

During testing, we found that the car cooled a lot better, to the point where it was having trouble getting up to operating temperature on mild days. A thermostat supplied by KTM was integrated to ensure that the engine and engine oil were not ‘overcooled’, which would have detrimental effects on the lubrication and life of the package. It allows us to bypass both radiators when the engine is under it’s operating temperature, and our parallel system gives the flexibility of isolating a single radiator if needed.

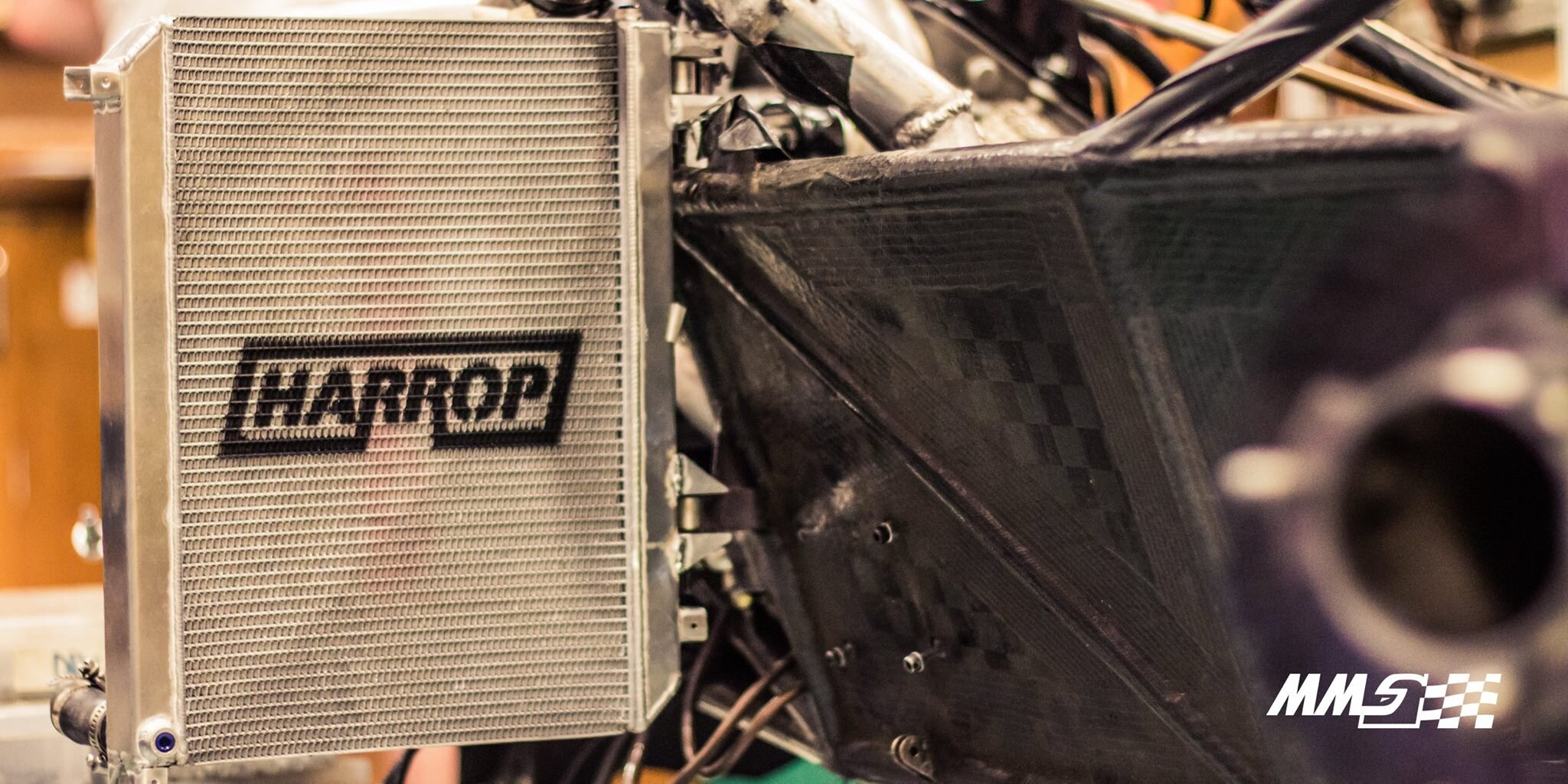

Now that the liquid side of cooling was sorted, we decided to look into how we could improve efficiency of the combustion process. One drawback of running a turbocharger is that a great amount of heat from the turbine (exhaust) stream is transferred through to the compressor (intake) stream, causing much less oxygen per unit mass to enter the combustion chamber. To overcome this increase in intake air temperature, a custom air-to-air intercooler was manufactured by Harrop, successfully lowering intake temperatures.

Through a detailed process of design, testing and validation, we have been able to overcome the problems we faced at FSAE-A 2015 and have been able to put together a better, successful cooling system to take to Europe and Australasia this year.