CARBON FIBRE COMPOSITE MONOCOQUE CHASSIS FOR A FORMULA STUDENT RACE CAR - Leon Shi & Kieran Rice 2019

The Final Year Thesis, is a technical engineering assignment undertaken by students of Monash University. Monash Motorsport team members often choose to conduct this assignment in conjunction with the team.

These theses have been the cornerstone for much of the team’s success. The purpose of the team releasing the Monash Motorsport Final Year Thesis Collection is to share knowledge and foster progress in the Formula Student and Formula-SAE community.

We ask that you please do not contact the authors or supervisors directly, instead for any related questions please email info@monashmotorsport.com

Summary

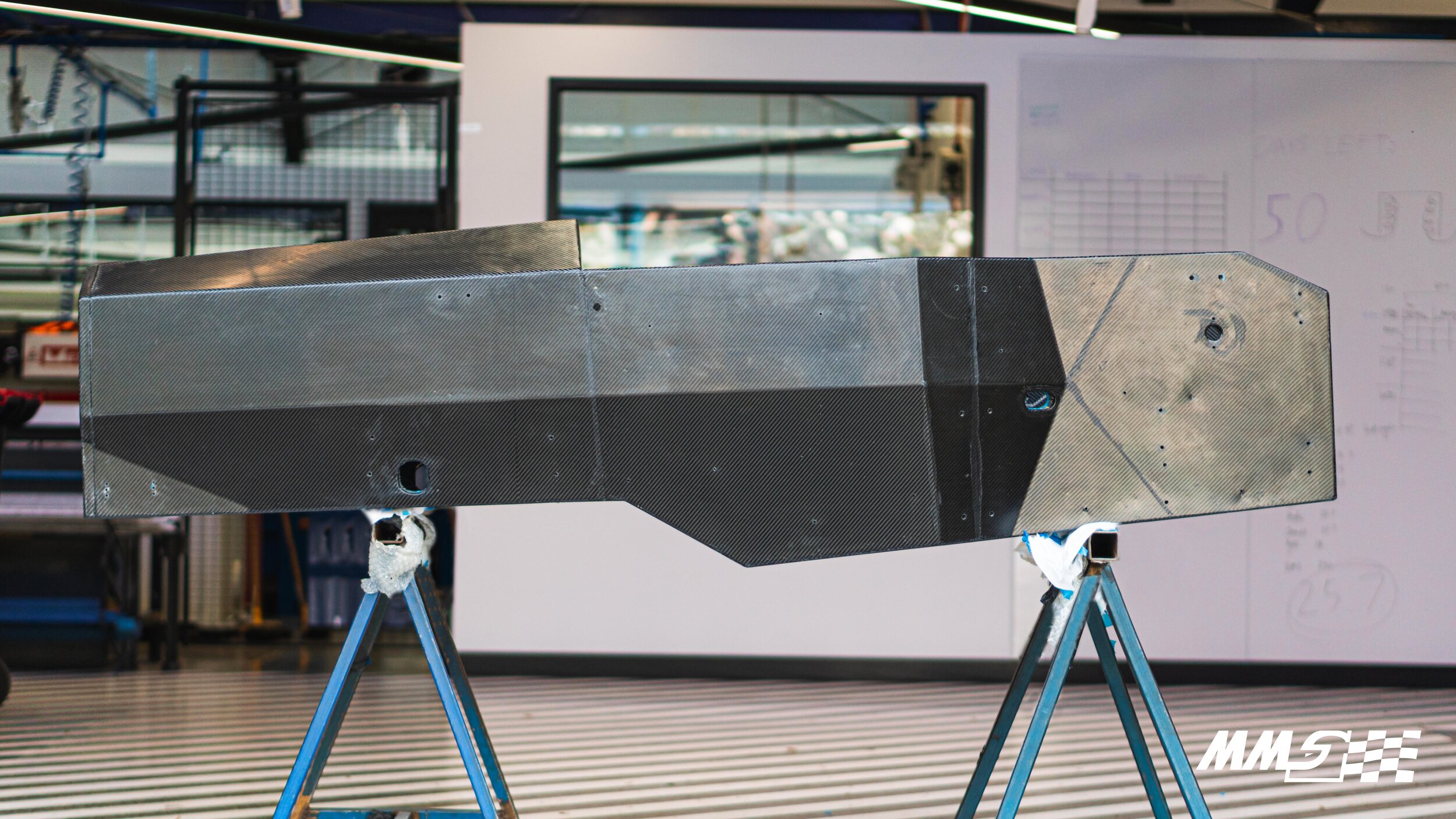

The work presented in this report is the culmination of over four years of development dating back to late 2014. 2019 saw the Monash Motorsport Formula Student team successfully implement its first pair of carbon fibre composite monocoque chassis, replacing the tried and tested tubular steel space frame.

To accomplish this objective, the project was divided into several key components. These included:

An understanding of the rules restrictions and guidelines associated with a composite chassis

An in-depth literature study of the behaviour of composite materials and sandwich structures

Geometry design of the monocoque with detailed considerations for packaging, manufacturability and outright performance

Structural finite element analysis with validation through physical testing

Manufacturing of the two monocoques

Post manufacture evaluation and further testing

Overall, every one of these individual tasks was either met or exceeded, resulting in two monocoques weighing in at 25.1kg and 26.3kg, with a physically tested torsional stiffness of 3551Nm/deg. This represented an almost 80% increase in chassis stiffness compared to the previous iteration steel space frame chassis. This project has also resulted in the development of new design tools specifically catered for the design of a composite chassis, which will be of major assistance to future monocoque designers at Monash Motorsport.

Chassis Types

The main function of the chassis is to maintain driver safety at all times. Secondary to this is to be able to transfer the tyre loads both in the longitudinal and lateral directions, as well as to internally package the driver controls and powertrain systems. The Formula Student rules are very open to design freedom in that they allow for three main chassis configurations.

Steel Space Frame

This is the most commonly used chassis configuration in Formula Student. The spaceframe is a truss-like frame structure, usually welded together using mild steel or 4130 chromoly round steel tubing. This form of chassis is the least expensive to fabricate which is why it is so popular for many teams in Formula Student. The usage of spaceframe chassis designs in the automotive industry dates back to the 1950s, with Mercedes being the first manufacturer to make use of a tubular spaceframe design in the 300SLR racing car, followed by the famous 300SL ‘gullwing’ road car. Variations of the tubular spaceframe are still used today in high performance vehicles, notably the Audi R8 sports car and the Australian Supercars Championship touring cars.

Figure 1 : M17-E steel spaceframe chassis.

Composite Monocoque

The word monocoque is of French origin, and the literal translation to English is single shell. As the name suggests, a monocoque is a structural component in which the outer body shell or skin is fully load bearing.

The history of the monocoque originates in the naval and aviation sectors, with the first widely known usage of a composite monocoque in automobile chassis design taking the form of theMcLaren MP4-1 Formula One racing car which competed in the 1981 Formula One season. Aluminium body monocoques had previously been used in motorsport as early as the 1960s with Lotus pioneering it in their Formula One cars [8]. The key motivator for moving to a monocoque design in a period when the spaceframe was standard was its lightness, stiffness and strength. This became very apparent early on to any doubters of the monocoque when John Watson crashed his McLaren MP4-1 heavily during practice for the 1981 Italian Grand Prix and walked away from the accident completely unscathed.

In modern day motorsport and Formula Student, the composite monocoque is nearly always constructed using sandwich panel technology. This consists of two composite laminates sandwiching an internal core structure in between. The external skins are usually

constructed using carbon fibre reinforced polymers (CFRP) and the core using a honeycomb cell structure from either aluminium or Nomex aramid. Other less commonly used material constructions can include aramid fibres such as Kevlar and foam cores.

A major stepping stone to the widespread adoption of a monocoque chassis in the Formula Student community is cost, as well as manufacturing time. The relatively exotic production methods, including the necessity for a composite autoclave for processing prepreg composites, drives the cost and complexity of chassis manufacture well beyond what is required for a steel Spaceframe.

Figure 2: McLaren MP4-1 composite monocoque chassis (foreground) with McLaren MP4-12 road car monocell.

Hybrid

A less costly solution to a full monocoque chassis in Formula Student is a hybrid chassis consisting of a monocoque tub for the front half and a steel spaceframe or rear subframe at the back. Here the driver is still fully protected by the monocoque structure, with the powertrain assembly being mounted via the rear subframe. This particular chassis design is most popular with combustion vehicles where accessibility to the engine is a high priority and is much easier to achieve without a monocoque structure impeding it.

Figure 3: Hybrid chassis of Rennteam Uni Stuttgart e.V. F0711-12, 2017.

In 2019 Monash Motorsport has designed two new vehicles from a clean slate: one combustion and one electric. In a continuation from the 2017-18 design philosophy, the team has placed a large emphasis on part compatibility and interchangeability between the two cars, as this reduces the manufacturing and design burden on the team as well as making spare components are easier to come by. The decision was made very early in the design process at the end of 2018 for Monash Motorsport to move away from a steel space frame chassis design to a full monocoque chassis design for both cars.

Conclusion

The design, testing and manufacture of all new monocoque chassis for Monash Motorsport in 2019 has been the culmination of over four years of research and development. Transitioning from the tried and tested tubular spaceframe chassis to a carbon fibre composite monocoque chassis has been a significant undertaking, requiring a whole new knowledge base, analysis tools and manufacturing skills within the team.

After an in-depth review of composite theory, new design tools have been created to aid future monocoque designers. FEA simulation tools using ANSYS ACP are able to predict composite panel 3 point bend failure loads and chassis installation stiffness with an error of less than 5% compared to physical testing data, while a MATLAB script has been developed to provide an early prediction on the strength of chassis hardpoint inserts used for localised loading of the monocoque. These tools will be able to reduce analysis time in the future and eliminate the need for extensive physical testing, both a time consuming and costly process.

The geometry design of the 2019 monocoques has been an ambitious one; aimed at allowing for a much larger aerodynamics package as a result of tighter and narrower packaging of the driver, suspension and powertrains. Input and integration from all parties was critical to achieving a design that would be satisfactory for everyone.

A laser cut and folded aluminium mould design saw drastic reductions in cost and manufacture time compared to the traditional composite tool manufacture process. To complement this, a low temperature curing GMS Composites EP-270 twill weave prepreg CFRP was chosen to be combined with a Plascore 5056 aluminium honeycomb core to form the sandwich panel construction. In total, two monocoques were produced by the chassis section in six weeks, weighing in at 25.1kg and 26.3kg: a phenomenal effort. Post NDT evaluation of the finished monocoques did reveal some manufacturing defects, however these were quickly rectified using validated composite repair techniques. A post repair torsional analysis test saw a recorded 3551Nm/deg chassis installation stiffness for the M19-C monocoque.

The 2019 monocoques have laid down the foundations for future successful chassis designs, but in order to continue the evolution from the best Formula Student team in Australasia to the best in the world there are a number of steps that we recommend are taken. These include changes to the geometry, materials, manufacturing techniques, analysis and testing conducted.